Vacuum Leak Testing for Package Integrity: Labthink’s Solutions and Best Practices

Understanding vacuum leak testing is crucial for ensuring the integrity and safety of your packaged products. As a supplier of testing equipment, we know that leaks can lead to product spoilage, compromised sterility, and significant financial loss. Implementing a reliable vacuum leak test procedure helps you maintain high-quality standards and meet regulatory requirements. This article explains the fundamentals to help you make informed decisions about your quality control processes.

Vacuum Leak Test Definition

A vacuum leak test is a non-destructive quality control procedure used to identify and locate leaks in sealed packages or containers. The test involves placing the packaged item inside a sealed chamber and evacuating the air to create a vacuum. If a leak is present, air or gas will escape from the package into the chamber. This is detected either by a pressure rise in the evacuated chamber in the Vacuum Decay method setup, or by observing bubbles escaping from the package while submerged in a water bath in the Bubble Emission method setup. This method is essential for verifying the seal integrity of packaging, ensuring it protects the contents from environmental factors. The reliability of this test depends on the use of calibrated precision test instruments to apply and monitor the vacuum level accurately. It is widely applied in industries like food, pharmaceuticals, and medical devices to prevent contamination and preserve product shelf life.

Vacuum Leak Test Procedure

The standard vacuum leak test procedure begins by placing the package into the vacuum chamber, which is then securely sealed. The air is evacuated from the chamber to a predetermined vacuum level, which is held for a specified time. During this period, the vacuum chamber is monitored for pressure change, indicating a leak. In bubble emission method setup, the package can be submerged in water, where a stream of bubbles will emanate from any leak path. The entire process must be carefully controlled, with parameters like vacuum level and dwell time set according to the package’s material and design specifications. We at Labthink provide equipment that automates much of this process, ensuring consistent and repeatable results. Proper procedure execution is critical for accurate pass/fail determinations and maintaining product quality.

Vacuum Leak Test Results

The test result is determined by comparing the observed pressure increase during the measurement cycle against a validated threshold. A result is considered a ‘Pass’ only if the pressure rise remains within the statistical limits of a non-leaking reference sample.

A pass result indicates that the package seal is intact and provides an effective barrier, which is critical for product safety and longevity. A fail result means a leakage in the packaging and the integrity of the container is compromised. These results are quantitative, allowing for comparison against established acceptance criteria and quality standards.

Accurate results help manufacturers identify flaws in their packaging processes, enabling corrective actions to be taken prevent non-conforming products from reaching the market.

Conclusion

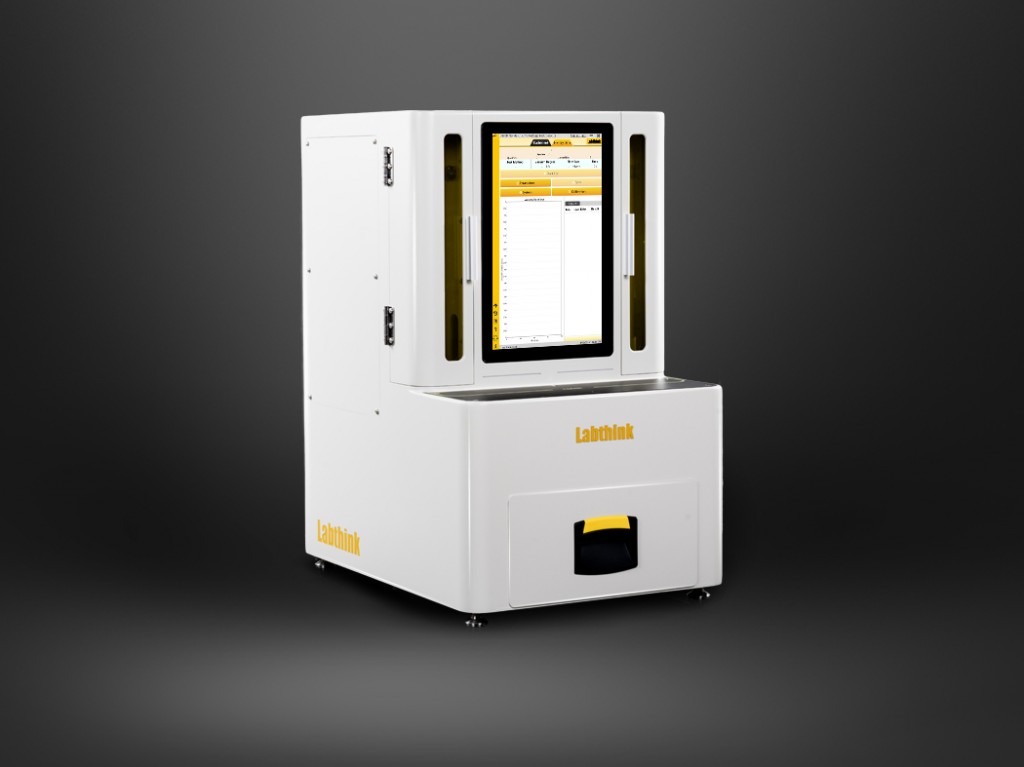

Labthink manufactures test instruments for evaluating packaging material physical properties such as leak and seal integrity, and tensile strength, as well as permeability test instruments that measure the transmission rates of gases like oxygen, water vapor, and carbon dioxide through packaging materials. These instruments are used for quality assurance in industries including pharmaceuticals and food. For your testing needs, we offer specific product models like the C190H Air Permeability Tester, the C403H Oxygen/Water Vapor Transmission Rate Test System, and the C690H Nondestructive Package Leak Detector.